Cutting & Stripping Equipment for

Mineral Insulated Cable

RINGING

Automatic Orbital Sheath Cutting

Fully automatic sheath cutting (grooving process) – orbital cuts into the material are program controlled (microprocessor control with counters) and carried out with high precision. Depth grooving adjustment according to the shield thickness and cable types. This minimizes overheating, reduces burrs and provides a good cut quality.

Ringing Machine

Cable Cutting

- Stationary cable grooved by a rotating blade wheel

- Fast cable machining: about 5÷15 seconds

- Very simple to setup and operate

- Cable stopper to correctly insert the cable on the position to be machined

- Internal PLC with display and keys for a total control

- Safety 2 Start buttons system with central Emergency/Stop button

- Wide range Multi point Clamping system

- Automatic motors standby when the machine is not in use

Micro Ringing Machine

Cable Cutting

- Stationary cable with grooving by rotating blade wheel

- Fast cable machining: about 4-8 seconds

- Very simple to setup and operate

- Cable stopper to correctly insert the cable on the position to be machined

- CNC system by means of two linked microprocessor controllers

- Automatic start system when he cable reaches its insertion stopper

- Automated clamping system by electromagnetic actuator

- Auto-select the groove depth based on the detected cable and settings

- LED lighted inspection window for manufacturing process control

- Automatic motors standby when the machine is not in use

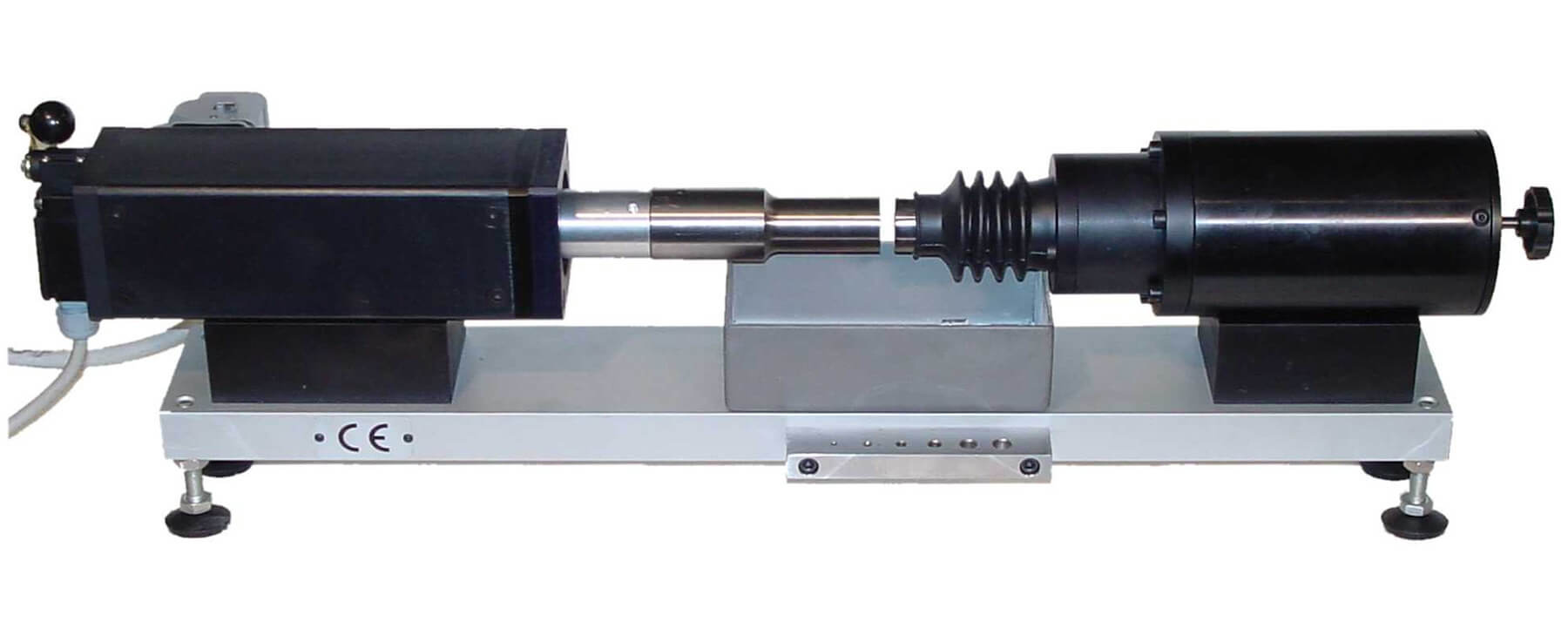

PULSUS

Ultrasonic Cable Stripping

Fully automatic stripping machine using powerful pulses of Ultrasonic energy to strip the sheath from the mineral insulated cable. The ultrasonic energy transfers to the insulation on contact and de-compacts and liquefies the powder. The result is that all the powder in the stripped section is cleanly removed leaving the conductors completely untouched.

Pulsus MA

Cable Stripping

- Fine settings to maximize Quality, Repeatability and Efficiency

- Made with robust materials to withstand heavy duty production

- Fast processing in about 1÷5 seconds

- Very simple to set-up and operate

- US instant power meter on panel

- Equipped with an additional Safety Foot-switch command lever

- Equipped with additional rubber bellows powder protection for ball bearing guide on the vibrating piston as spear part

Pulsus CFA

Cable Stripping

- Designed to work on mineral insulated cables to ensure maximum quality, repeatability, and efficiency

- Made with robust materials to withstand heavy dut protection

- Fast processing in about 1/5 seconds

- Very simple to set up and operate

- Great OLED graphical display that report setup values and show current status

- Knob to fine adjust of the ultrasonic power to be applied

- Knob to fine adjust to the electromagnetic plunging and vibrating force

- Switch to select the type of vibrating force

- Outputting the record of single process (optional)

- Remotely controllable equipment for implementation on an automatic production line