Wire Straightening, Guiding & Feeding Equipment

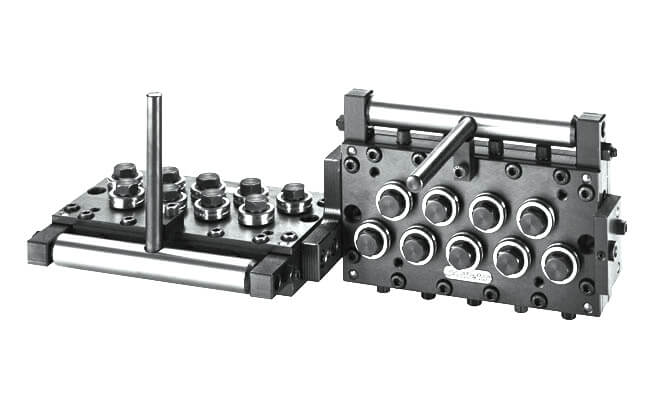

AS/AD Type

AS = Single Plane / AD = Dual Plane

- Mainly used on drawing machines

- Single and dual plane straightener models

- Eccentric roller open/closing device (lever)

- From 5 ~ 13 rollers per group (5, 7, 9, 11, 13) or (5+5, 7+7, 9+9, 11+11,13+13)

- Roller diameters 13 ~ 80 mm (0.5″ ~ 3.15″)

- Adjustable rollers on the upper row

- Rollers available for light or heavy duty applications

- Rollers are standard “V” groove but can accommodate square, hexagonal and triangular wire profiles (other profiles can be accommodated as well as customized profiles)

ASM/ADM Type

ASM = Single Plane / ADM = Dual Plane

- Mainly used on spring, screw and wire bending machines

- Single plane and dual plane straightener models (set of vertical and horizontal planes)

- From 5 ~ 13 rollers per plane (5, 7, 9, 11, 13) or (5+5, 7+7, 9+9, 11+11,13+13)

Rollers independently adjustable – top & bottom rows - Roller diameters 13 ~ 90 mm (0.5″ ~ 3.54″)

- ASM/ADM models also available for larger wire diameters – roller dia. up to 110 mm

- Quick release and gripping cam for roller opening / closing

- Adjusting screw for cam positioning brake – avoids undesirable release caused by any vibration during operation Concealed design avoids accumulation of material filings, grime & dirt in moving parts

- Rollers are standard “V” groove but can accommodate square, hexagonal and triangular wire profiles (other profiles can be accommodated as well as customized profiles)

- Wire guide included

ASF Type

optional guide bushing

- Used mainly on the vertical axis of coiling machinery Also used on wire netting machines

- Regulates wire bending

- Supplied with or without guide bushing

- Suitable for 0,3mm to a maximum diameter of 15mm

- Single and dual plane straightener models for ASF type (ASF 1 = Single Plane / ASF 2 = Dual Plane)

- From 5 ~ 9 rollers per plane ((5, 7, 9) or (5+5, 7+7, 9+9)

- Roller diameter 13 ~ 80 mm (0.51″ ~ 3.15″) for ASF type

- Rollers available for light or heavy duty applications

- Rollers are standard “V” groove but can accommodate square, hexagonal and triangular wire profiles (other profiles can be accommodated as well as customized profiles)

ADV Type

Wire straighteners for Welding Wire

Introducing a wire straightener specifically designed for the high speed processing and spooling of welding wire (TIG). As various factors like high speeds, processed material composition, wire tensile strength, roller/bearing lu- brication and inferior roller materials, amongst others, may influence the rapid wear of standard rollers available in the market place today, we are offering a wire straightener with special tungsten carbide roller sleeves with special high speed lubricated double bearings. Tungsten Carbide roller sleeves are profiled with ”V” grooves suitable for your wire specification.

Roller range is suitable for a complete wire range of 0.035” (0.88 mm) up to approximately .098” (2.4 mm) can be supplied with either 90°, 100° or 120° “V” groove profiles.

- 0.8 to 1.6 mm wire dia = 90° “V” groove profile

- 1.6 to 2.0 mm wire dia = 100° “V” groove profile

- 2.0 to 2.4 mm wire dia = 120° “V” groove profile

Below are some eminent points of the Cometo welding wire straighteners:

- Tungsten Carbide Roller Sleeves – designed for high speed applications and prolonged durability

- Linear speed 115 ft/sec (35 m/sec) – suitable for high speed applications

- Cam action rapid opening/closing device – reduces setup time

- Adjustable rollers – extreme precision in final product

- Dual bearing roller assemblies – provides extended maintenance cycle Roller dia – 23 mm

D type

Wire Straightener

- Wire straightener recommended for wire mesh production

- Minimum space required for installation

- Only one row of rollers adjustable

- Screw type adjusting system

- Quick scissor-opening system

- Suitable for wire dia 0,3mm to a maximum dia of 14mm

- Single plane straightener models

- From 5 ~ 7 rollers per plane ((5, 7)

- Roller diameter 22 ~ 80 mm (0.86″ ~ 3.15″)

- Rollers available for light or heavy duty applications

- Rollers are standard “V” groove but can accommodate square, hexagonal and triangular wire profiles (other profiles can be accommodated as well as customized profiles)

S-150

Single Plane & Dual Plane

Wire straightener in steel with rollers diameter 150mm, suitable for the processing of full round wire diameter from 16mm to 30mm, and of ca- bles and pipes to a diameter of 45mm.

The wire straightener S150 is available in single version with 5 rollers, two of them are positioned on the upper row and three in the lower row. Draw- ings available to enable the assembling of two units at 90°, in order to get one double device with 5+5 rollers, as shown in the picture.

This wire straightener is available with manual regulation or with manu- al servo driven regulation equipped with a reduction-gear ensuring a lighter manual regulation, or with a roller open /close hydraulic system. The rollers can be supplied in steel or with plastic coating suitable for the processing of pipes and cables.

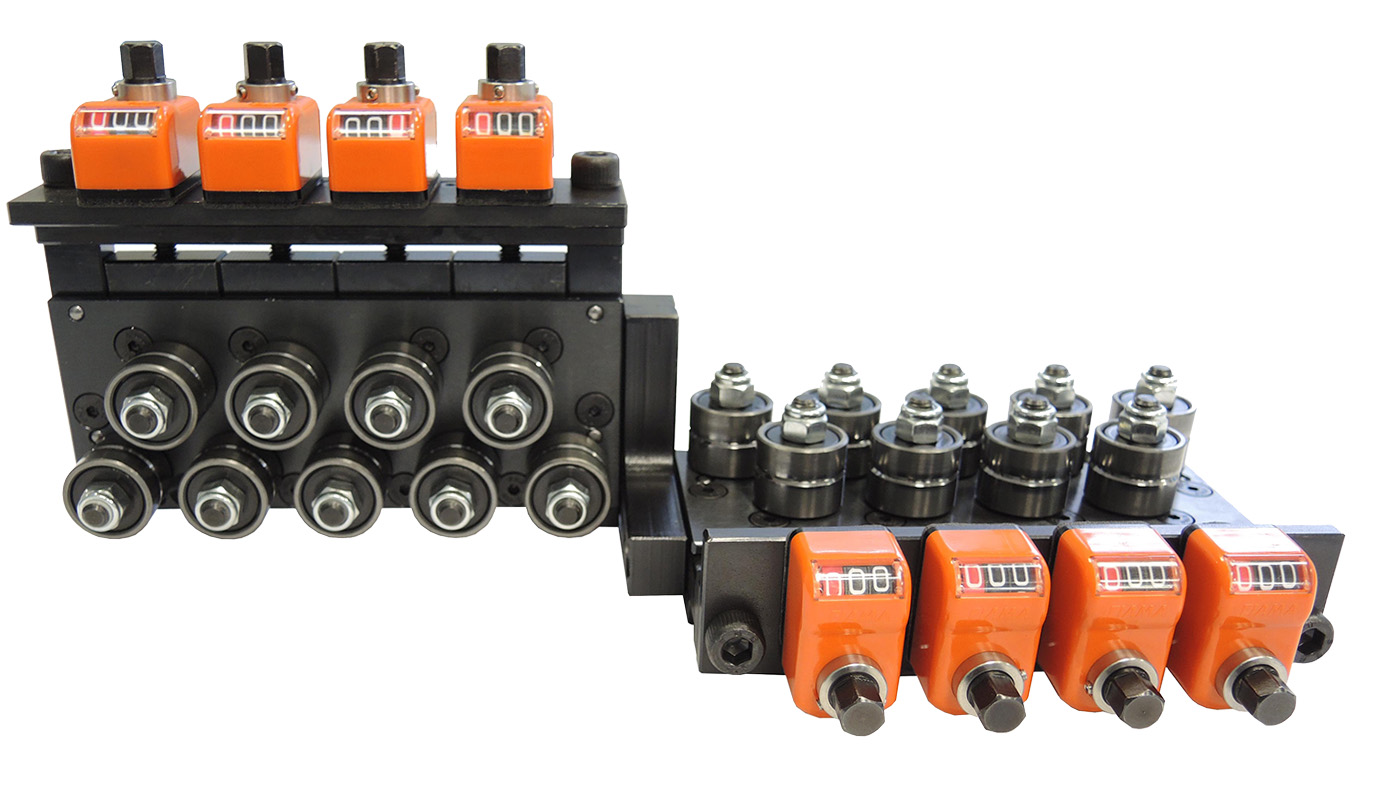

RF-110 c/w

Numeric roller position indicators/ adjuster

- Suitable for high tensile material

- Easily installed in existing line

- Numeric roller position

- Indicators/adjusters for accurate recording of roller

- Positioning for future reproducibility

- Single Plane, 5, 7 & 9 roller units available

- All Rollers individually adjustable

- Rollers profiled to accomodate 10 mm to30 mm wire diameter

- Also suitable for pipe diameter up to 45 mm dia

- Roller dia – 110 mm

Spare Rollers

Replacement Straightener Rollers

- Standard range of ‘V” grooved rollers – (90° ~ 120° “V” grooves)

- “U” grooved rollers and any other groove profile available upon request – square, triangular, flat, hexagonal—almost any shaped wire

- High quality bearings ground to a high tolerance of concentricity Special high speed, dual bearing tungsten carbide rollers for tire cord & welding wire also available

- CA type straightener rollers – single roller bearing suitable up approximately 3 mm wire dia.

- CAR type straightener rollers – single row bearing for medium duty applications – this roller has a higher outside ring allowing greater groove depth suitable for approx. 3 mm – 9 mm wire dia. CAR2 type straightener rollers – similar to CAR type but houses a dual type bearing for higher load capacity. Greasing/lubrication access

- CAW type straightener rollers – dual bearing construction with 63 HRC hardened steel sleeve for high load capacity and large wire diameters. Greasing/lubrication access

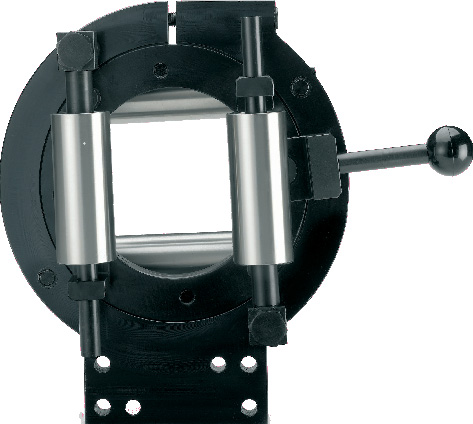

GAP type

Wire Guide

- Different combinations of wire, plate & cable guides

- Easily guides different type profiles on various machinery

- Self centering

- Hand wheel operated

- Adjustable stop at selected diameter

- Accommodates wide range of material sizes

- Variety of mounting and attachment holes located on unit

- GAP-RO type guides – 4 roller oblique adjustable cable/wire/plate centering

- GAP-RV type guides – 2, 3, 4 and 5 roller type units (dual vertical type roller units and parallel and vertical guide roll combinations)

GQ type

Wire Guide (Box type)

- 4 hardened rollers – 60 ~ 62 HRC

- Square flange

- Compact design – easily affixed to an existing line

- For wire or cable from 1~ 30 mm (0,04″ ~ 1,2″)

CC type

Cable Centering Device

- For diameters 50 – 100 – 150 mm—250 mm (2″ – 4″ – 6″ – 8”)

- Self centering, locking and release system in one operation

- Selected diameter setting secured by locking screw

Spare Wire Guide &

Cable Centering Rollers

Guide rollers

- Guide rollers for wire, cable, tube and steel strip

- Wide range of rollers with ground surface finish and standard rollers hardchrome plated (min. 20 m)

- Other surface coatings also available upon request

- RU-type guide rollers – assembled with bearings to suit selected shaft/pin attachment for 7 mm-30 mm dia.

- RU1-type guide rollers – rollers with shaft/pin for securing one end – M8 to M30 shaft diameter

- RU2-type guide rollers – rollers with shaft/pin securing both ends – M6 to M18 shaft diameter

- Non standard rollers and shaft/pin available on request

AL6 & AL12 Type

Wire Feeders

- Wire feeders for wire, metal strip and tube

- For wire diameters 1 ~ 20 mm (0.04” ~ 0.78”)

- Various power options for roller pressure adjustment – screw type, cam type, hydraulic and pneumatic pressure

- Compact design – suitable for set-up on almost any machine

- Can add multiple modules – for pulley and motor driven requirements

- AL 6 Feeder Units – 1, 2 and 3 module units

- For wire diameters 0.04” – 0.275” (< 1 mm – 7 mm)

- Maximum speed – approx. 393 ft/min (120 m/min)

- Roller diameter – 2.56” (65 mm)

- Roller groove profiles machined to your wire, rod or flat bar specification Rollers can be multiple grooved for different wire diameters

- AL 12 Feeder Units – 1, 2 and 3 module units

- For wire diameters 0.23” – 0.78” (6 mm – 20 mm)

- Maximum speed – approx. 590 ft/min (180 m/min)

- Roller diameter – 4.80” (122 mm)

- Roller groove profiles machined to your wire, rod or flat bar specification

- Rollers can be multiple grooved for different wire diameters

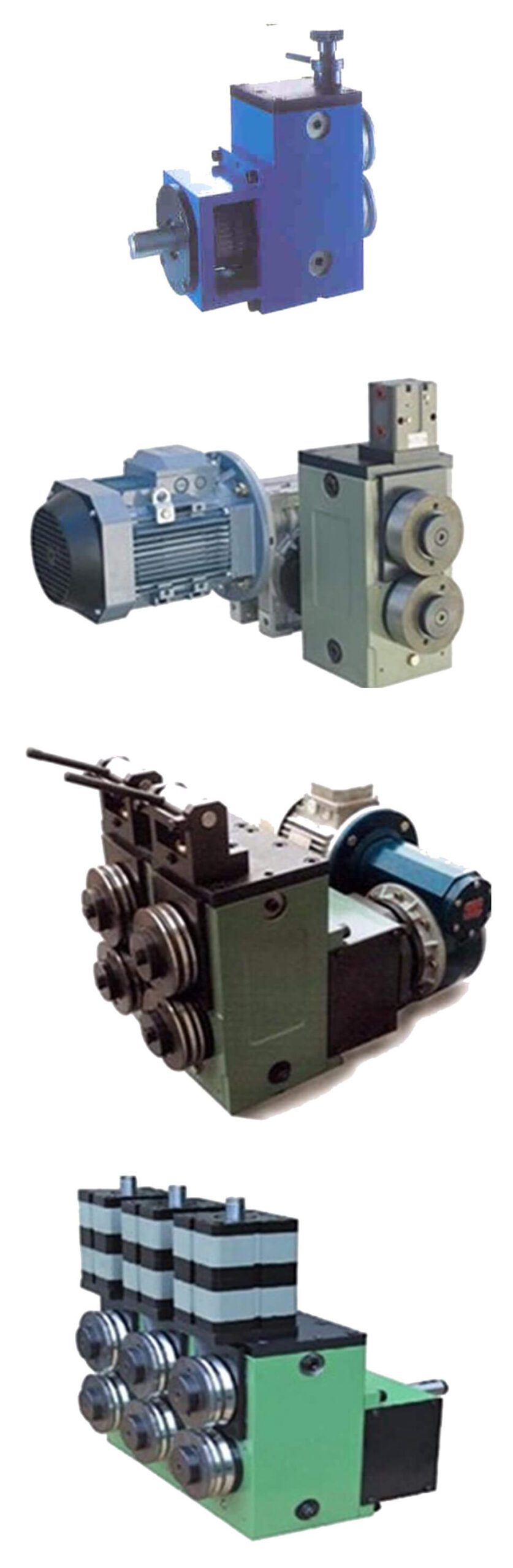

Rotating Die Holder

Performance and Criteria

- Direct cooling of die (prevents heat accumulation on wire)

- Providing a perfectly round final wire

- During each passage through the die holder and on all capstans, the wire is lubricated by continuous addition of drawing powder or solution Increased drawing speed

- Increased die life

- Maintaining lower drawing temperatures

- Reduced machine downtime (due to wire breaks and die change)

- Easier access for periodical maintenance

- Selection of slow or fast die rotation speeds

- Various installation options

- Single and Double Die applications

- Multi-voltage motors

- Short or Long series steel lubrication box – suitable for powder or liquid lubrication

- The die-holder is available in four different sizes covering a die diameter range from 38 up to 100mm:

- CFRMD431 = for die up to 43mm diameter – for 1 mm -5.5 mm wire dia

- CFRMD551 = for die up to 55mm diameter – for 5.5 mm -10mm wire dia

- CFRMD701 = for die up to 70mm diameter – for 10 mm -15 mm wire dia

- CFRMD100 = for die up to 100mm diameter – for 15 mm -20 mm wire dia

PFR43

rotating die-holder

- Cometo’s PFR43 rotating die holder has been engineered to be used

on dry drawing machines. - The rotary movement insures improved wire lubrication through the die and helps to preserve the wire’s roundness without deforming it.

- The PFR43 is available with or without the lubrication tank engineered to contain the stearate.

- Rotating die holder advantages:

- quick change die holder: just loosen the locking cap a few rotations

and extract the die in the cooling tank, - quick coolant check,

- die coolant bathes the die in an open tank, without creating any

pressure guaranteeing improved duration of the seals.

- quick change die holder: just loosen the locking cap a few rotations

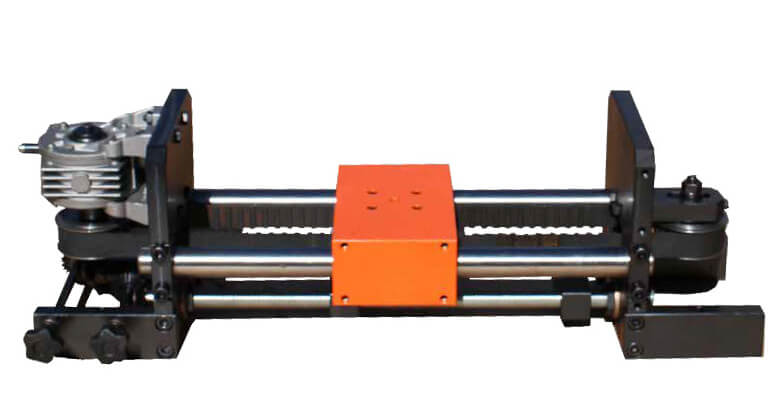

STR28 & STR40

Traversing Units

- The traverse unit STR is available in two sizes:

- STR28 with hardened rods diameter 30mm, 35kg of translation force

- STR40 with hardened rods diameter 40mm, 70kg of translation force

- Easily integrated into any spooling/take up operation and can be tailored to your requirements.

- Pneumatic reversal unit guarantees shortest possible reversal time

- Available side thrust – up to 35 kg (77 lbs.) for the STR-28

- Up to 70 kg (155 lbs.) for the STR-40

- Choice of different ratio gear reducers for pitch selection – to be selected

- Easy connection with take-up units

- Very low maintenance

- Traverse / Stroke width – up to 1718 mm (67.6”) for STR-28 – to be selected

- Up to 1632 mm (64.25”) for STR-40 – to be selected

Mechanical traverse units model STR suitable for installation on spooling/take up machines – both new and earlier models. These units are equipped with a pneumatic reversing system allowing its carriage to be guided on hardened steel rods by means of a toothed pulley belt. Its continuous working reliability and minimal maintenance ensures suitable winding of the wire.

TAG-10 Type

Guillotine type cutter model

- Suitable for the cutting of wire from 1mm to maximum diameter 12mm. The TAG10 also offers the possibility to cut plate and profiled material with maximum width 10mm.

- Cast iron frame, steel construction and compact design.

- Centralized oil lubrication system

- Hardened and ground tool steel cutting blades and material guides

- TAG10 can be combined in a straight & cut line or a simple feed line application

- CUTTING CAPACITY: 1mm -12 mm dia.

- INPUT PRESSURE:

- Pneumatic unit : 1kg/cm2 (min) – 6 kg/cm2 (max)

- Hydraulic unit : 50kg/cm2 (min) – 150 kg/cm2 (max )

- CUTTING PRESSURE :

- Pneumatic unit : 1.800 kg,

- Hydraulic unit : 4.500 kg CUTTING

- TIME : approx 0.4 seconds for 12mm material

- The unit is available in three versions:

- pneumatic

- hydraulic

- motorized with brushless motor

ECM-05 Type

Electronic Cutting Unit

- Suitable for both round or shaped profiles up to maximum diameter 5mm. Available with “bush to bush” blade or open blade

- The cut timing is 0,15 second

- Driven by brushless motors but is also available in a pneumatic version

- Also also available in an electronic version.

- Can be added to a a straight & cut line